Better bio ink for 3D bioprinting

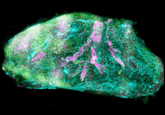

In a step forward for 3D bioprinting and regenerative medicine, scientists have developed an improved bio-ink to improve the printed gel structure.

Over the last few years, 3D printing technology has advanced, offering researchers the chance to develop ways of 3D printing with biological materials such as cells, which can further regenerative medicine. Inkjet bioprinting is advantageous since the small droplet size makes it easier to precisely create and arrange the individual components required to construct 3D tissues and organs. However, obtaining biological ink that can pass easily through the printer’s dispenser, adhering the droplets to one another, and quickly stabilizing the structure remain challenging. Now, scientists at the University of Osaka have come up with an improved drop-on-drop ink jetting system, solving some of these problems.

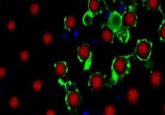

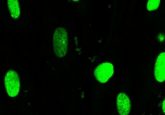

Drop-on-drop inkjet bioprinting refers to dropping a minute amount of hydrogen peroxide immediately after another ink droplet containing a polymer, an enzyme, and cells .

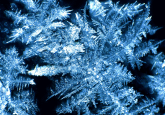

To use inkjet bioprinting efficiently, the bio-ink’s viscosity is a crucial factor. It needs to be low enough to pass through the printer easily, but it should thicken right after printing to stabilize and hold the structure together. Until recently, sodium alginate was commonly used as the gelling agent for inkjet bioprinting, but this was not suitable for quick hydrogelation. Instead, Shinji Sakai , first author of the study, and his team used a horseradish peroxidase enzyme in the presence of hydrogen peroxide, resulting in cross-linking the polymer molecules and instantaneous hydrogelation.

“These results were very exciting for us. We did not expect hydrogelation to be so fast while using this enzyme. We had tried using other enzymes like tyrosinase and transglutaminase in bioprinting, but could not prepare 3D structures due to the slow hydrogelation rates,” said Sakai.

Sakai believes in the strong potential of inkjet bioprinting and feels there is a lot of opportunity for advancement. “For constructing complex structures, multiple bio inks should be used in the inkjet printer. At present, the maximum number of inks used at one time is only four. We are currently working towards making a library of bio inks and are looking for support from a company for realizing this project,” said Sakai.