Building bots with biology

With full step-by-step instructions, almost anyone can build millimeter-sized, walking bio-bots for any application.

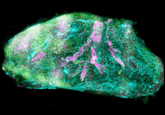

This bio-bot schematic shows an engineered skeletal muscle tissue coupled with a 3-D printed flexible skeleton. Optical stimulation of the muscle tissue makes the bio-bot walk across a surface in the direction of the light.

Credit: Janet Sinn-Hanlon from the University of Illinois Urbana-Champaign

A teensy weensy robot is finding a lot of job opportunities as more scientists realize its potential.

After nearly five years developing and perfecting a millimeter-sized bio-integrated robot called a “bio-bot,” researchers at the University of Illinois Urbana-Champaign recently published their designs and procedures in Nature Protocols, hoping to inspire engineers around the world to “build with biology.”

“We were inspired by the mechanics of organic materials and wanted to streamline a way to build our bots with multiple potential uses,” said Ritu Raman, a postdoctoral fellow at UIUC’s Micro and Nanotechnology Lab and first author of the study. “With our protocol, we addressed how to use what already exists in nature and tried to replicate those systems through tissue engineering and 3-D printing.”

The team developed bio-bots by culturing engineered muscle cells in soft hydrogels, allowing the cells to form into muscle-ring actuators—a mechanism that converts energy to motion. Then they coupled these muscle rings to a 3-D printed skeleton, creating a millimeter-scale machine. Each bio-bot is capable of “walking” by contracting its muscle cells, which are controlled by either electrical or optical stimuli.

There were minor downsides to electrical stimulation, including whole-muscle excitation and the need to design biobots with geometric asymmetry in the skeleton design—one leg had to be longer than the other. As a result, the bot could only walk in a single direction . “Regular robots don’t function or look [lopsided] like that; they should be able to walk in any direction, and you shouldn’t have to change the design every time,” Raman explained.

Optogenetics proved to be a better method for control. To prevent whole-muscle stimulation, researchers simply shine 470-nm light pulses on parts of the bot to change direction—shine left to move left, and shine right to move right. This offers more precise 2-D navigation control, and there’s no need to change the overall design of the bio-bot.

Another interesting effect of bot stimulation was increased muscle strength. “Whether we mechanically stretched the muscles, thereby increasing the alignment of muscle fibers, or repeatedly stimulated them either with electrical or optical pulses every day for 10 or 15 minutes, we noticed larger muscles and greater force output. The muscles were getting exercise,” Raman said.

This realization was important because this is the demonstration that optogenetics can non-invasively strengthen muscles and that bio-bots are responsive and adaptive to a variety of environmental stimuli. The team believe that bio-bots will be extremely helpful for basic science researchers tackling many problems in health, security, and the environment.

“These tools are going to accelerate a number of fields in tissue engineering, including organ-on-a-chip disease models and sensing for remote diagnostics,” said Kara McCloskey, an associate professor at the University of California, Merced School of Engineering, who was not involved with the study. “My undergrad and grad students used part of the bio-bot designs for building contractile muscle tissue for heart repair.”

With the step-by-step instructions for building bio-bots available to everyone, others can take a crack at answering this group’s remaining questions or explore their own different research avenues. Right now, bio-bots are being considered for fundamental muscle development and disease studies, high-throughput drug testing, sensing and then neutralizing chemical toxins, using different cell types—such as neurons or endothelial cells—for basic research, and much more.